In the spirit of the COP 30 Presidency’s call for a global mutirão – a collective effort to mobilize climate action – the Business Council for Sustainable Energy (BCSE) will lead a business delegation to COP 30 in Belém, Brazil that will bring forward credible solutions, partnerships, investments, and ideas to accelerate the energy transition and decarbonize agriculture, buildings, industry, and transportation. This case study is part of BCSE’s Granary of Solutions to deliver emissions reductions, increase resilience, and meet energy transition goals worldwide.

Highlights:

- Cloud-based data allows a multi-national renewable energy developer to optimize the reliability and efficiency of its technologies

- 410,000 estimated tCO2e reduced over 24 months from thermal fleet catches – equivalent to 95,635 gas-powered passenger vehicles driven for one year

- Improvements help Enel make progress toward its net-zero emissions by 2040 goal

Case Study:

Enel is the world’s largest private renewable energy operator and power distribution company. With operations in 31 countries and on five continents, it brings energy and services to more than 55.4 million households and businesses. Because of its large fleets of diversified power generation assets – all of which produce a tremendous amount of data – Enel is constantly looking for new solutions to extract more value from its data. So Enel harnessed its AVEVA portfolio, from edge data capture solutions to predictive analytics, to optimize the reliability and performance of its assets, cut greenhouse emissions, and operate more sustainably.

“Our commitment is not only to reduce our fleet unplanned unavailability, but also to make all our power plants more efficient, said Andrea Pica, Head of Remote Predictive Diagnostic Area for Enel Green Power.

Cutting greenhouse gas emissions with predictive analytics

Enel has an ambitious target of net-zero emissions by 2040, in line with the goal of keeping global warming below 1.5°C. The EGP business line was already using its TS Cross – Remote predictive diagnostics center to support maintenance optimization across its 28 plants, 61 generation units, and 1285 assets. Recently, Enel focused specifically on cutting greenhouse gas (GHG) emissions with predictive analytics, so it could reduce its need for fossil-based replacement power.

Replacement power in geothermal and thermal power plants is necessary to maintain grid stability when the plant is unable to produce its expected output. This can happen due to maintenance, equipment failures, or unforeseen shutdowns. And since Enel’s replacement power is generated from less efficient, more emission-intensive assets, it is crucial to mitigate equipment failure before it becomes critical. Early resolution of minor incidents requires less maintenance effort and replacement power than addressing escalated issues. So Enel used AVEVA solutions to help provide early warnings on these minor incidents so it could resolve issues before they become high-criticality incidents.

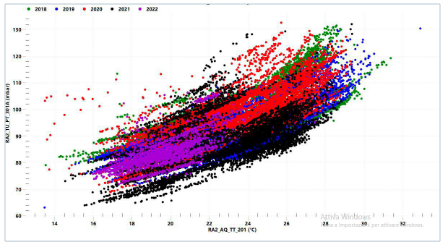

Tracking generator power over time has allowed Enel to develop a predictive maintenance strategy that detects equipment failure early and reduces the need for fossil-based replacement power.

Enel used AVEVA Predictive Analytics and AVEVA PI System to monitor the health and performance of over 1,285 assets, including 837MW of its geothermal fleet, using 4,310 predictive models and over 47K AVEVA PI System tags, across four countries and two continents.

The results were impressive. Early detection of equipment failure significantly reduced unplanned downtime and the need for inefficient fossil-based replacement power. In terms of GHG emissions, Enel estimates it estimated avoid 410,000 tCO2e over 24 months from thermal power fleet catches. This is equivalent to 95,635 gas-powered passenger vehicles driven for one year, or over 55,000 homes’ energy use for one year. Additionally, its geothermal power fleet estimated avoid 4,800 tCO2e per year – equivalent to 1,000 homes’ electricity use for one year.

With predictive analytics models and early detection, it’s estimated that EGP was also able to reduce indirect GHG emissions as a result of less process waste, less equipment scrap, and fewer on-site maintenance activities.

Remote predictive diagnostic center: Optimizing maintenance activities

As is often the case, more sustainable operations also mean increased performance of assets and reduced maintenance costs. Enel’s remote predictive diagnostic center has been a crucial part of its operations for a number of years, allowing it to maximize the availability and performance of all assets and catch potential failures before they happen.

The center uses predictive analytics to measure the degradation of equipment and plan maintenance based on a variety of factors to optimize expenditure and performance.

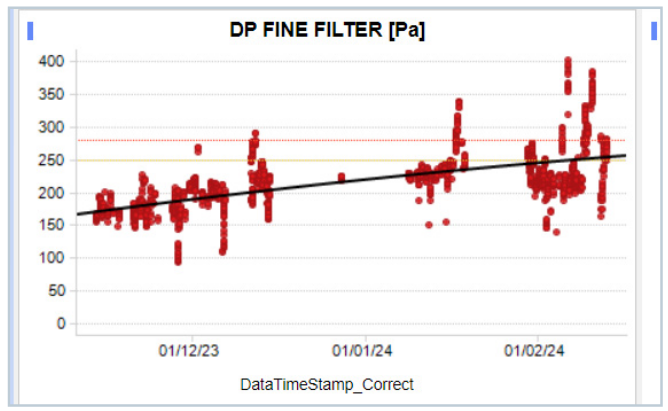

For example, to make maintenance decisions about its gas turbines, Enel isolates and measures factors such as gas turbine filter fouling and compressor degradation in order to optimize maintenance activities. Using AVEVA Predictive Analytics, Enel can evaluate the “remaining life” of this equipment by comparing DeltaP with the one suggested by OEM for the replacement and giving to power plants a data driven support in order to plan the best moment for the replacement.

Enel tracks air filters DeltaP to make the best, most cost-efficient maintenance decisions.

In the case of changing turbine filters, the diagnostics team has used their predictive analytics models to avoid over- or under-maintenance. They discovered that, in one instance before implementing this condition-based monitoring, the filter was changed when its remaining economic life was still more high. The change was premature. In another instance, the change was overdue – the degraded condition of the filter combined with the increase in gas price meant the excess gas burn of the turbine cost Enel about €18,000 per week. Now, Enel can pinpoint the optimal time to change its turbine filters to maximize their use and value.

Another area where predictive analytics models have helped Enel optimize is in transient analysis. Disturbances or sudden changes in operating conditions can throw a wrench in traditional maintenance calculations.

Compressor surge events, for example, can cause rapid fluctuations in condenser pressure in steam turbines which, if not caught by the operator, can cause the plant to shut down suddenly. Restarting can take several hours, leading to lost production.

Using specific gas turbine models developed for transient monitoring that used past turbine behavior, RPD Center and the power plant’s operators were able to identify a temperature and pressure anomaly in one turbine installed in a power plant during a start-up phase. In a previous incident, a compressor surge had deeply damaged the turbine blades, and the restoration required 78 days of plant unavailability. By catching the anomaly in time has been estimated to have avoid in terms of repair costs about €3.1M. Since 2020, Enel has caught about 461 failures and estimated avoided losses of almost €47M using AVEVA Predictive Analytics.

Expanding operations demand scalable cloud-based solutions

Enel has faced new challenges as its operations have expanded. New plants mean new data, and new data mean new demands on Enel’s existing data infrastructure. Enel has increased the flexibility, scalability and availability by proving its data infrastructure through integration with the CONNECT industrial intelligence platform. By using this hybrid cloud architecture, Enel will futureproof its investment and scale data infrastructure to meet dynamic business demands.

Using AVEVA Adapters and AVEVA Edge Data Store, the company can collect and store data from remote or small legacy assets outside the primary network and make this data available to local decision makers. Data can then be aggregated in a central, cloud-based data hub using CONNECT data services. Because the original edge data is stored locally before transfer to the cloud, disruptions in connectivity never result in lost data.

Gathering consistent data from remote or smaller assets across geographies can be a challenge. For example, photovoltaic panels are very large. Before, Enel could only collect data at the inverter level, which doesn’t provide a holistic picture of asset health.

In order to collect and extract value from more granular data at the panel level, Enel used AVEVA Adapter for MQTT and AVEVA Edge Data Store. This way, Enel can increase the availability of this data in order to perform analyses and drive optimization.

In addition to collecting more granular equipment data, a failure or shutdown affects data flow, and Enel needed a backup strategy to retrieve that missing data. It can’t afford to manually load CSV files from each SCADA – and it can’t afford to lose that data completely. By using AVEVA Adapters for OPC UA, installed with PI Connector for OPC UA in the PI Gateway, Enel can now recover that data from a centralized environment. Because the adapters use the existing infrastructure of AVEVA PI System, there’s no need for new installations or having to go through a VPN, which is good for cybersecurity and helps Enel save money.

“If we were acquiring all of this data through the standard channels, we would probably overload our networks,” said Alvise Rossi, Plant Information Platform Engineer for Enel. “Using AVEVA’s edge solution allows us to get that data without overloading the existing infrastructure.”

Conclusion

Enel continues to push the boundaries of renewable energy innovation, and AVEVA technology is helping it accelerate this journey of innovation. The digital infrastructure it has built allows Enel to continue to grow and unlock new efficiencies with data-led insights. By harnessing predictive analytics, industrial AI, and scalable cloud-based solutions, it can make better, more sustainable operational and business decisions. AVEVA is proud to be a partner along Enel’s journey as a leader in sustainable energy for the world.